Company Overview

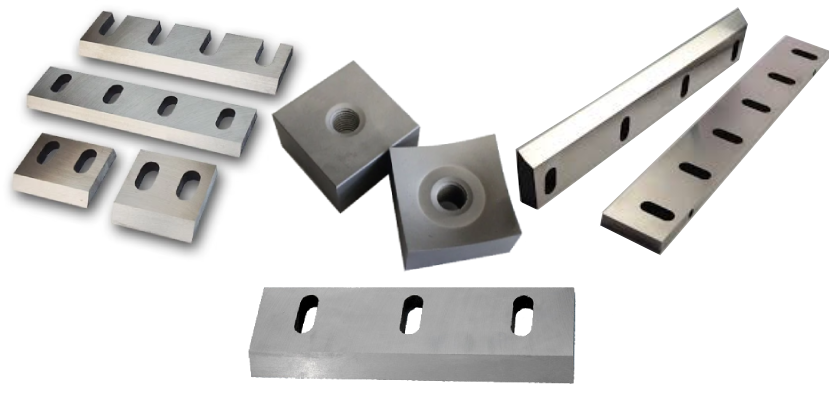

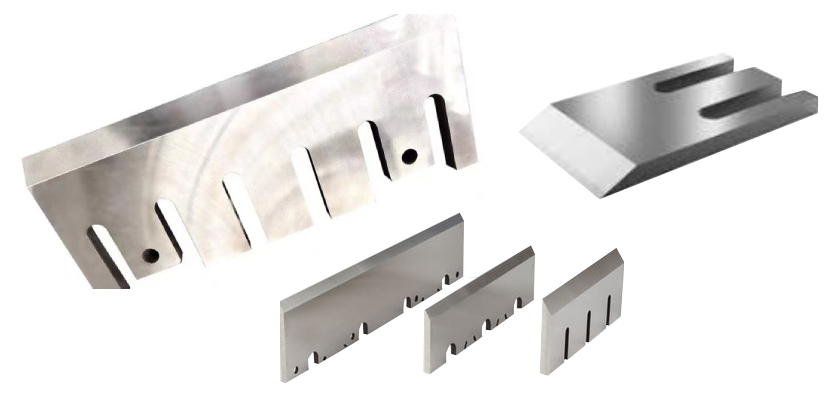

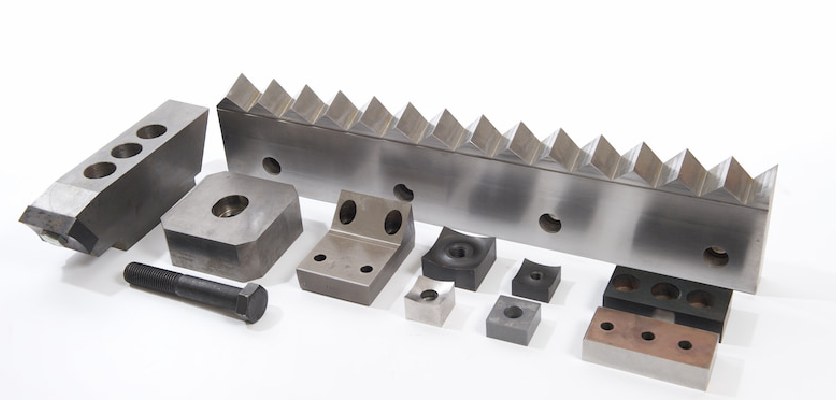

Khosla Tools and Equipment Est 1995 is a leading manufacturer of precision industrial knives and saws, providing solutions for industries such as wood processing, pulp, packaging, paper, steel, food processing, plastics. With a specialization in wood chipper knives, we offer a wide range of custom-engineered products, including slitter knives perforation blades and peeling blades. Our products are meticulously crafted to meet the highest standards of durability, precision, and performance, ensuring that our clients experience maximum efficiency and minimum downtime in their operations.

Our manufacturing facility is equipped with state-of-the-art technology, including

VMC’s,CNC’s, wire cutting machine, cryogenic treatment and precision salt bath heat treatment, precision surface

grinders which significantly enhances the longevity and performance of our products. We prioritize the use of

high-grade materials and stringent production processes to deliver solutions that exceed industry standards.

As an ISO 9001-2015 certified company, we are committed to maintaining consistent quality control and

pursuing continuous improvement across all facets of our business. In addition to our ISO certification, Khosla Tools

holds a Z-Certification, further reflecting our commitment to international quality standards.

At Khosla Tools, we understand that each client’s needs are unique, which is why we offer customized solutions tailored to specific operational requirements. Our customer-centric approach ensures that we work closely with our clients to develop products that not only meet but exceed their expectations. From the initial consultation through to product delivery, our team is dedicated to providing unparalleled service and technical support. With 30 years of experience, Khosla Tools and Equipment is the preferred partner for businesses seeking high-performance industrial knives and tools. We believe in building lasting relationships with our clients by consistently delivering products that improve productivity and contribute to their long-term success.